STONE FRUIT

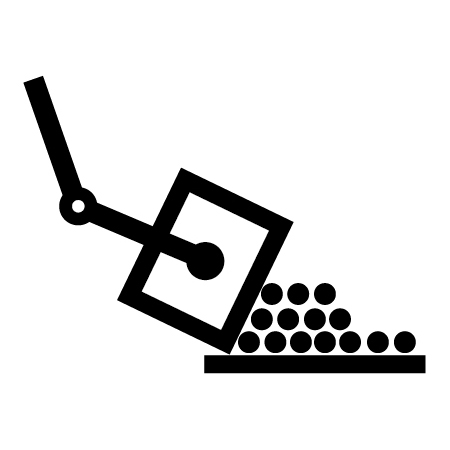

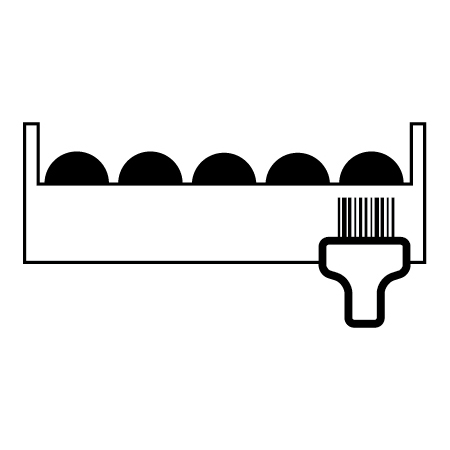

The grading and packaging of stone fruits can be organised into direct packaging or as two-stage work (pre-sizing and packaging) for annual volumes of between 100 and 15,000 tonnes.

Furthermore, processing the packaging of peaches with four colours (peach, nectarine, white and yellow), a multitude of packages, and orders for same-day delivery make the task complex.

Anticipating the grading and packaging in order to honour customer orders means taking major financial risks. Two-stage working helps you to meet demand more efficiently.

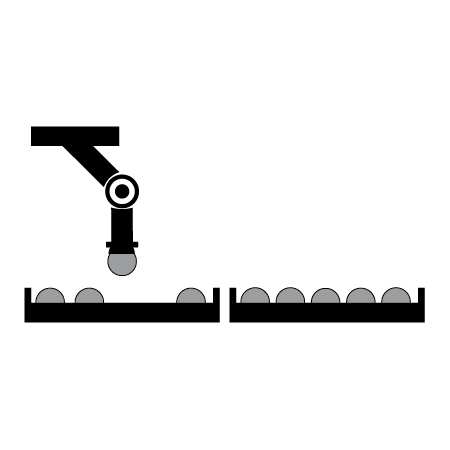

Backed by its experience, MAF RODA AGROBOTIC has invested heavily in producing sensors for colour, diameter, external defects and internal defects specific to stone fruits. The electronics installed on the fruit conveyors are not standard: they are genuinely dedicated to stone fruits. The key challenge for pre-sizing and grading lies here: sorting better so as to sell better and manage costs better. In this context, and when there are large volumes to market, the pre-sizing of stone fruits simply goes without saying.

Furthermore, processing the packaging of peaches with four colours (peach, nectarine, white and yellow), a multitude of packages, and orders for same-day delivery make the task complex.

Anticipating the grading and packaging in order to honour customer orders means taking major financial risks. Two-stage working helps you to meet demand more efficiently.

Backed by its experience, MAF RODA AGROBOTIC has invested heavily in producing sensors for colour, diameter, external defects and internal defects specific to stone fruits. The electronics installed on the fruit conveyors are not standard: they are genuinely dedicated to stone fruits. The key challenge for pre-sizing and grading lies here: sorting better so as to sell better and manage costs better. In this context, and when there are large volumes to market, the pre-sizing of stone fruits simply goes without saying.

MAF RODA provides you with complete solutions for streamlining your packaging process.

From the raw harvested produce through to delivery to your customers we are attentive to your needs, and we will supply you with our analysis, suggesting machines suited to your mode of operation and in compliance with the regulations.

Reliable and robust, our equipment benefits from after-sales support and services guaranteeing the long-term sustainability of your installations.

The key to the success of your project: your experience combined with our know-how.

Graders

Electronic sorting

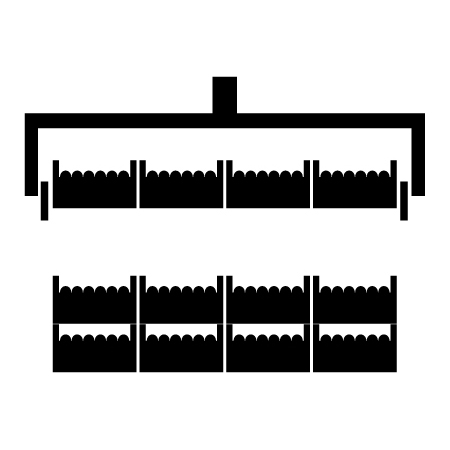

GLOBALSCAN

External control:

- diameter,

- colour,

- shape,...

SOFTNESSCAN

Internal defect control:

Detection system for "soft spots" and "soft zones"

INSIGHT 2T & 2RH

Measurement system of sugar rate (BRIX index)