Electronic sorting

Since 1979, MAF RODA AGROBOTIC has developed its own electronic sensors for sorting fruits and vegetables, and designed cutting-edge technology equipment to meet requirements for measuring weight and external/internal quality: colour, volume, diameter, density, shape, and even the sugar content (BRIX index), or checking for internal defects, such as internal browning, for example.

Weight sorting

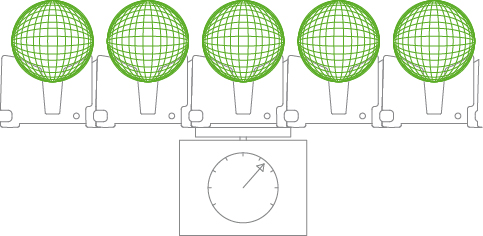

Weight measurement takes place by means of an electronic strain gauge associated with a mechanical weighing conveyor installed on the grader, thereby guaranteeing precise, individual weighing of each item of produce.

The electronic weight sorting system is suited to most of the graders developed and designed by MAF RODA AGROBOTIC, such as:

- the POMONE,

- the PLUMONE,

- the EXOTICA,

- the INTEGRA,

- the INTEGRITA,

- the ONEWAY,

- the FREEWAY,

- the GENESIS,

- the LONGWAY,

- the GRAPE SIZER.

External quality sorting

The external quality sorting systems developed by MAF RODA AGROBOTIC analyse the surface aspects of fruits and vegetables to detect predefined parameters of colour and shape, for example, along with defects on the skin such as puncture marks, mould and bruising. These sensors guarantee optimum selection of the produce for packaging.

- OPTISCAN:

The OPTISCAN system acquires and analyses various colour and infrared images for each product rotated in the camera field of view, guaranteeing that the products are sorted according to their colour and their shape.

This optical system is composed: - of lighting and a reflecting chamber for the grader,

- of a vertical camera, per grader lane.

- GLOBALSCAN:

The GLOBALSCAN external analysis system acquires and analyses multiple colour and infrared images for each product rotated in the camera field of vision, guaranteeing that the products are sorted according to their colour, their shape and their external quality.

The GLOBALSCAN can be used for analysing the entire surface of produce such as apples, kiwis, citrus fruits, tomatoes, peaches, apricots, plums, persimmon, avocados, mangoes and pomegranates.

- VIOTEC :

Thanks to the use of two dual-spectrum cameras (UV + RGV), this electronic sensor dedicated to citrus fruits makes it possible, when selecting produce, to discard fruits presenting zones of mould undetectable to normal vision by analysing superimposed images in UV and IR.

This electronic sensor is associated with the GLOBALSCAN.

- VIOSCAN :

The VIOSCAN detects surface imperfections of the skin of citrus fruits, such as puff and crease, chimera, and clear rot, using dual-spectrum cameras (UV + RGV).

Internal quality sorting

- IDD 4 :

This detection system has been developed to check for internal fruit defects, such as internal browning and virescence. The analysis is conducted via the transmission of near-infrared lighting through produce such as apples, onions, oranges, melons and pears, in particular.

This electronic sensor is unique on the market, and is a patented MAF RODA AGROBOTIC system.

- INSIGHT 2T & 2RH :

This latest-generation sensor system measures the sugar content (BRIX index) via near-infrared spectroscopy of such produce as apples, kiwis, mangoes, peaches, nectarines, plums, apricots, avocados, cantaloupe melons, tomatoes and citrus fruits.

- SoftnesScan (SSD2 - Softness Spot Detection) :

This measurement system analyses deceleration via the mechanical scanning of produce. When selecting fruits, it detects in this way "soft fruits" and "soft zones" on produce such as kiwis, peaches, nectarines, plums, apricots and Paraguayo peaches.