M & R PACKING

1st cherry packer of California to utilize technology from MAF

USA

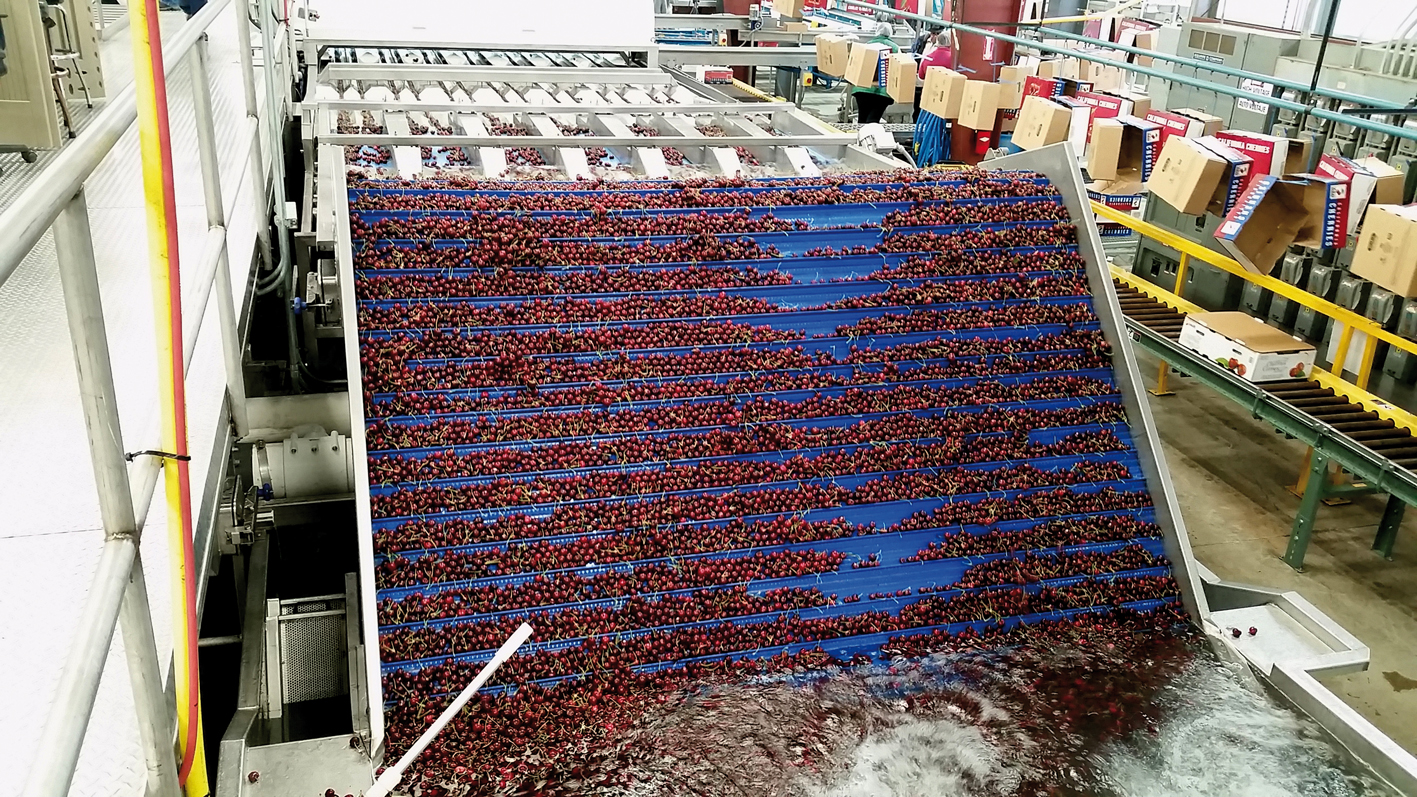

M & R PACKING took advantage of MAF’s newest cherry grading technology by installing a 14 lane by 13 control led outlets for sorting cherries by size, color and defect. The implementation of MAF’s CherryScan 6 cherry optical system allowed the removal of not only external defects but cherries that were “too soft” for the commercial market.

The application of the new MAF grading system allowed the facility to become 100% electronically sized cherries with before this latest installation only a select size structure and 30% of the flow was optically sized. The other aspect of the new line was the installation and use of 8 new MAF high speed filler that allowed M & R to run each carton style whether in bulk or with pouch bag mani folds that adjusted automatically to the proper height in order to minimize the drop distance of the cherries into the container being used. The customer’s operational personnel were trained on the use and features of the CherryScan optical system by showing the simple and easy to manage adjustments of the grade and size parameters that allowed the packinghouse to optimize the results being desired.